Kuhn - MDS 8.2

|

Designed for a wide variety of crop operations, the MDS .2 Series offers many features and options to succeed in almost any application. A simple PTO drive and rugged low-maintenance gearbox operate twin spreading discs that offer working widths up to 80’ (depending on the product applied) to finish large areas quickly and efficiently. Operators will appreciate the increased capacity of the available hopper extensions to work longer between refills, while the octagonal bottom reduces bridging and sticking for even cleanout. Redesigned metering outlet controls offer both electric and hydraulic options and the position of the metering slides can be easily viewed from the tractor seat for improved operator comfort. Optional border control and banding attachments direct product to where it can provide the greatest return on investment – feeding the crop. |

|

Designed to Withstand Tough Conditions

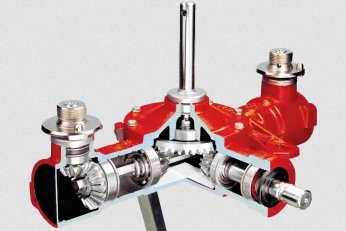

All MDS spreaders utilize a simple 540 rpm PTO drive. Contained within the cast-iron case are the components to drive the spreading discs and hopper agitator. This drive system has been designed for long life with minimal maintenance, as the gearbox oil only requires changing every 10 years under normal operating conditions. |

|

All KUHN fertilizer spreaders go through a proven multi-step finishing process that includes mechanical and chemical cleaning followed by a top-quality powder-paint application and baking. This ensures optimal corrosion and scratch resistance, fading resistance, acid resistance, and increased abrasion durability. |

|

Improved Material Flow

The hopper on the MDS .2 has been reshaped into a more octagonal design. Similar to the design of our larger Axis® fertilizer spreaders, the angles improve material flow to the centrally located metering outlets. This reduces bridging and promotes complete hopper emptying with all types of granular materials and seeds. A rotating agitator at the bottom of the hopper also helps to keep material flowing freely. Optional agitators are available for special applications such as grass seed, powdery materials, or sticky materials. |

|

All MDS spreaders utilize the Direct Flow Control (DFC) system for rate control. For a given working width and ground speed, changing the opening of the metering slides by a given percentage will change the application rate by the same percentage. On the .2 models, the metering slide opening scales are mounted on the front of the spreader to keep them cleaner and for comfortable viewing from the operator’s seat. |

|

Tailored to Meet Your Operation's Needs

Hydraulic Outlet Control

|

|

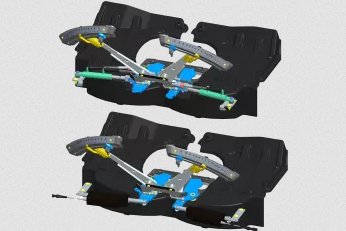

MDS spreaders can spread up to 80’ (pass-to-pass working width) depending on disc selection and the properties of the material. In general, oddly shaped and/or less-dense granules will be restricted to narrower patterns. Adjusting the length and position of the paddles on the discs creates the ideal spread pattern for each material. M1C discs come standard and are designed for working widths up to 59’. Optional M2 discs feature redesigned paddles optimized for 60’-80’ spread patterns. Both disc types offer the option of VXR hard-coated paddles for even greater durability. |

| Download Brochure | Download |