ID # 34913381

Grasshopper 440 61" Deck

Call for Price

Overview

Specifications

features and benefits

|

Model

440

Category Name

Lawn / Garden

Year

2024

Sale Type

New

Manufacturer

Grasshopper

Fuel

Gasoline - unleaded

Brakes

Dynamic braking through hydrostatic transmission.

Crankshaft

Horizontal

Displacement

60.6 cu. in. (993 cc)

Fuel Capacity

12 U.S. Gal. (45.4 l)

Height (ROPS)

69.5 in. 176.5 cm)

Cooling System

Air

Height (Seat Back)

47.0 in. (119.4 cm)

Lubrication System

Pressure Lube/Filter

Height (Seat Cushion)

31.5 in. (80.0 cm)

Type/Horsepower/Cylinders

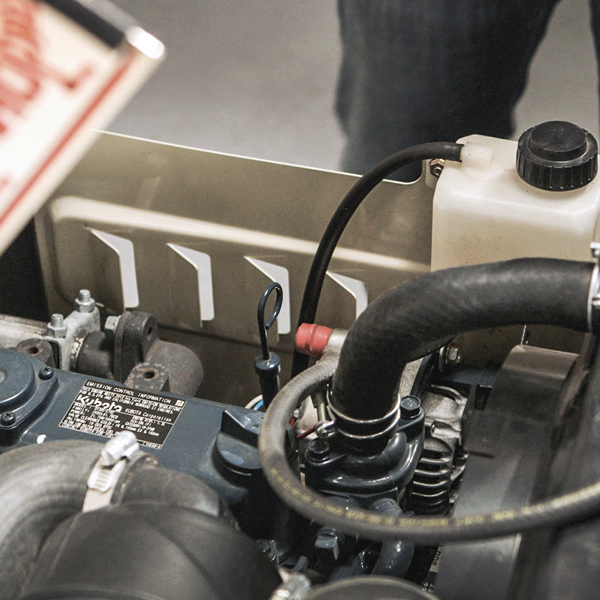

Vanguard Big Block EFI, V-twin with Electronic Throttle Control

Weight (Uncrated) – 61" Deck

1320 lbs. (598.7 kg)

Deck Width (Mulch*) – 61" Deck

62.5 in.* (158.8 cm)

Deck Width (Side Discharge) – 61" Deck

74.5 in. (189.2 cm)

Drive Wheels - Standard (4-ply Rated) – 61" Deck

26x12x12 turf, 6-ply rated

Length (midmount W/ DuraMax® Deck - Mowing Position) – 61" Deck

86.0 in. (218.4 cm)

Features & Benefits

Model

440

Category Name

Lawn / Garden

Year

2024

Sale Type

New

Manufacturer

Grasshopper

Quantity

0

Fuel

Gasoline - unleaded

Brakes

Dynamic braking through hydrostatic transmission.

Crankshaft

Horizontal

MODEL 440

MODEL 440

.jpg)

.jpg)

.jpg)

.jpg)